Working of Magnetic Suspension System

1. Introduction about Magnetic Suspension System:

In the realm of cutting-edge automotive technology, Magnetic Suspension Systems stand as a testament to innovation and engineering prowess.

These systems have revolutionized the traditional approach to vehicle suspension, offering a dynamic and responsive solution.

In this article, we delve into the intricacies of Magnetic Suspension Systems, exploring their construction, types, and the fascinating science behind their operation.

2. What is the Magnetic Suspension System?

The Magnetic Suspension System, often referred to as MagneRide or Magnetic Ride Control, is a sophisticated automotive suspension technology that employs electromagnetically controlled dampers.

Unlike conventional suspension systems that rely on mechanical components, magnetic suspension systems utilize magnets and sensors to adjust the vehicle's damping characteristics in real-time. This adaptive nature allows for a seamless balance between ride comfort and dynamic handling.

3. Types of Magnetic Suspension System:

Magnetic Suspension Systems come in various types, each catering to specific applications and requirements. The primary classifications include passive and active magnetic suspension systems, each with its unique characteristics. Let's delve deeper into these types to understand their functioning and advantages:

(a) Passive Magnetic Suspension System:

In a passive magnetic suspension system, the damping properties are controlled by the inherent characteristics of the magnetorheological fluid. This fluid, typically comprised of ferrous particles suspended in an oil-based liquid, changes its viscosity in response to a magnetic field. The suspension components, such as shock absorbers or dampers, are filled with this fluid.

When an external magnetic field is applied, either through the movement of the vehicle or by an electromagnetic device, the ferrous particles align, affecting the fluid's viscosity. This change in viscosity subsequently alters the damping properties of the suspension system.

In simpler terms, as the vehicle encounters varying road conditions, the fluid adapts its characteristics to provide an optimal balance between ride comfort and handling performance.

Passive magnetic suspension systems are generally simpler and less complex than their active counterparts, making them cost-effective and reliable. However, they might not offer the same level of real-time adaptability as active systems.

(b) Active Magnetic Suspension System:

Active magnetic suspension systems take the concept a step further by incorporating a complex electronic control system. These systems utilize sensors and actuators to continuously monitor and adjust the suspension settings in real-time, providing instantaneous responses to changing driving conditions.

In an active system, various sensors, including accelerometers, wheel-speed sensors, and body position sensors, constantly feed data to an electronic control unit (ECU). The ECU processes this information and determines the optimal damping settings for each wheel.

It then sends commands to adjust the electromagnetic field within the dampers, influencing the magnetorheological fluid's viscosity and, consequently, the suspension characteristics.

The active nature of these systems allows for a higher degree of customization and adaptability, making them ideal for performance-oriented driving scenarios. They can provide a smooth and comfortable ride during normal driving conditions and instantly switch to a firmer setting for improved handling during spirited driving.

(c) Semi-Active Magnetic Suspension System:

Between the extremes of passive and active magnetic suspension systems lies the semi-active variant. Semi-active systems combine elements of both passive and active technologies to strike a balance between performance and simplicity.

In a semi-active system, the suspension settings can be adjusted in response to driving conditions, but the range of adjustment is more limited compared to a fully active system.

This compromises some real-time adaptability but still provides a dynamic driving experience, making it a practical choice for a wide range of vehicles, including both luxury and sports cars.

The semi-active approach often results in a compromise between cost, complexity, and performance, making it a popular choice for manufacturers looking to enhance ride quality and handling without the added expense of a fully active system.

The choice between passive, active, or semi-active magnetic suspension systems depends on factors such as cost, intended application, and desired performance characteristics. Each type offers a unique blend of comfort and handling, showcasing the versatility of magnetic suspension technology in the automotive world.

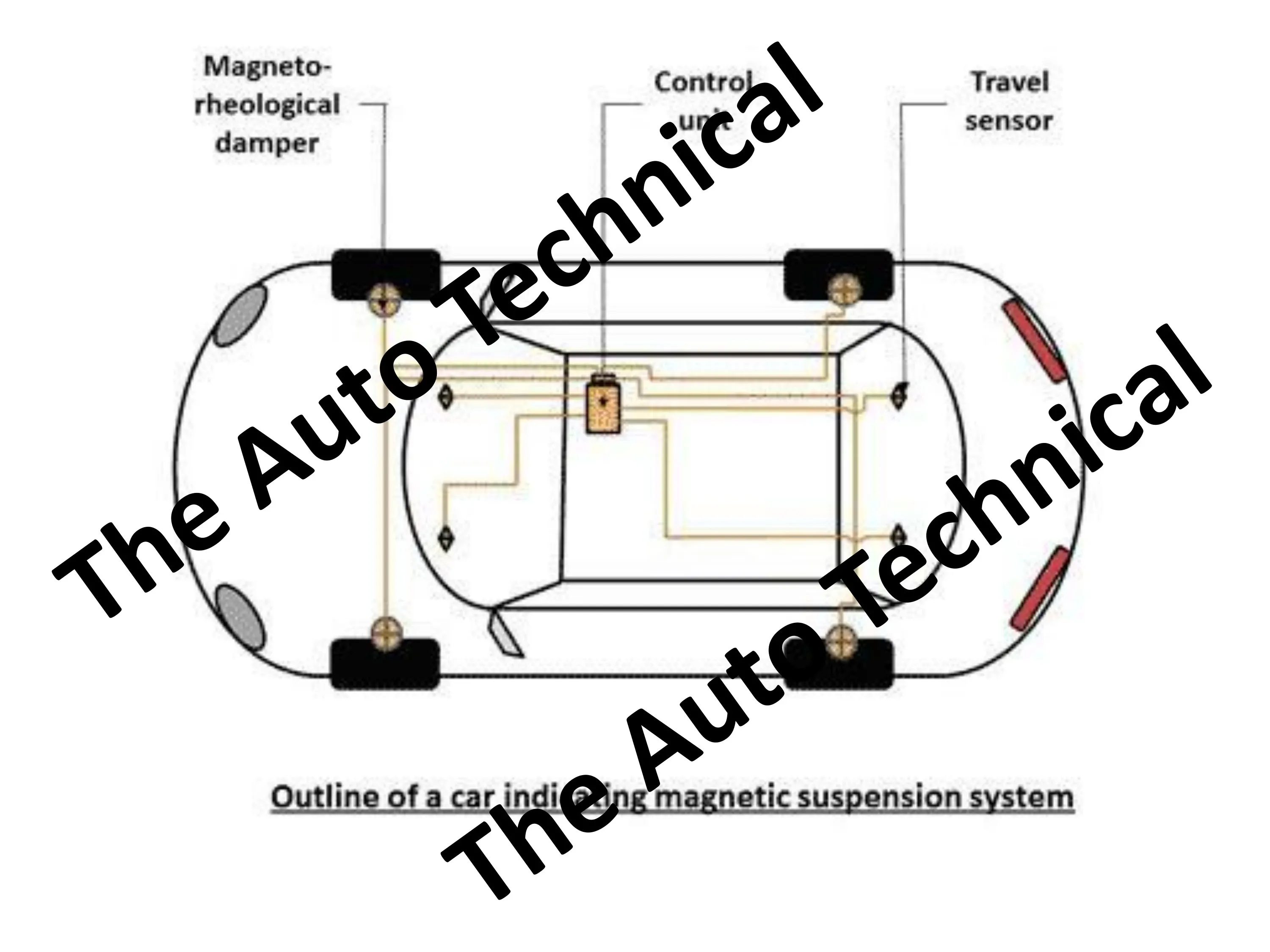

4. Construction of Magnetic Suspension System:

The construction of a Magnetic Suspension System involves intricate engineering to integrate electromagnetics, sensors, and fluid dynamics. The key components work cohesively to ensure the system's effectiveness in providing a dynamic and adaptive ride. Let's explore the essential elements of the construction of a magnetic suspension system:

(a) Electromagnetic Dampers:

At the core of the magnetic suspension system are the electromagnetic dampers. These dampers consist of several key components:

(b) Piston Assembly:

The piston contains the magnetorheological fluid, a special fluid that changes its viscosity in response to a magnetic field.

(c) Electromagnet:

Positioned around the piston, the electromagnet generates the magnetic field. The strength of this field is crucial for controlling the fluid's viscosity and, consequently, the damping characteristics of the suspension.

(d) Control Valve:

An integral part of the damper, the control valve regulates the flow of magnetorheological fluid within the system. It adjusts the damping force based on the electromagnetic field strength.

(e) Magnetorheological Fluid:

The choice of magnetorheological fluid is critical to the system's performance. This fluid typically consists of tiny ferrous particles suspended in an oil-based liquid.

The size and composition of these particles determine the fluid's response to the magnetic field. High-quality fluid ensures consistent and reliable changes in viscosity, allowing for precise control of the suspension.

(f) Sensors:

Various sensors are strategically placed throughout the vehicle to monitor critical parameters. These sensors include:

(g) Accelerometers:

Measure the vehicle's acceleration, deceleration, and lateral forces.

(h) Wheel-Speed Sensors:

Monitor individual wheel speeds.

(j) Body Position Sensors:

Track the position and movement of the vehicle's body in relation to the chassis.

These sensors provide real-time data to the electronic control unit (ECU), allowing the system to adapt to changing driving conditions.

(k) Electronic Control Unit (ECU):

The ECU acts as the brain of the magnetic suspension system. It processes the data received from the sensors and makes decisions about the optimal damping settings for each wheel.

The ECU then sends signals to adjust the electromagnetic field within the dampers, orchestrating the system's response.

(l) Power Supply:

A reliable power supply is essential to ensure the continuous operation of the electromagnetic dampers and the electronic control unit. The power supply provides the necessary electrical energy for the system to function efficiently.

(m) Mounting Hardware:

The components of the magnetic suspension system need to be securely mounted within the vehicle. This includes robust mounting brackets, fasteners, and other hardware to withstand the forces and vibrations experienced during regular driving conditions.

(n) Seals and Joints:

To prevent fluid leaks and maintain the integrity of the system, seals and joints are incorporated at critical points. These components ensure that the magnetorheological fluid remains contained within the dampers, preserving the functionality of the system.

The construction of a magnetic suspension system is a sophisticated integration of electromagnetic principles, fluid dynamics, and electronic control. The synergy between these components allows the system to adapt dynamically to changing driving conditions, providing an optimal balance between ride comfort and handling performance. This advanced construction is a testament to the continual evolution of automotive technology.

5. Working of Magnetic Suspension System:

The working of a Magnetic Suspension System is a marvel of engineering, combining electromagnetics, fluid dynamics, and real-time control to provide a dynamic and adaptive ride. Let's delve into the step-by-step process of how these systems operate:

(a) Sensor Inputs:

The process begins with various sensors strategically placed throughout the vehicle. These sensors continuously monitor key parameters, including:

(b) Accelerometers:

Measure the vehicle's acceleration, deceleration, and lateral forces.

(c) Wheel-Speed Sensors:

Monitor the speed of each wheel individually.

(d) Body Position Sensors:

Track the position and movement of the vehicle's body in relation to the chassis.

(e) Data Processing by the Electronic Control Unit (ECU):

The collected data from the sensors is fed into the electronic control unit (ECU). The ECU serves as the brain of the system, processing this real-time information and making decisions about the optimal damping settings for each wheel.

(f) Determining Damping Settings:

Based on the sensor inputs and predefined algorithms, the ECU calculates the appropriate damping force required for each wheel. This calculation considers factors such as vehicle speed, acceleration, cornering forces, and the condition of the road surface.

(g) Adjusting Electromagnetic Field:

The key to the magnetic suspension system lies in the electromagnetic dampers. The ECU sends signals to adjust the strength of the electromagnetic field within each damper. This field influences the magnetorheological fluid contained in the damper.

(h) Magnetorheological Fluid Response:

The magnetorheological fluid, which comprises ferrous particles suspended in an oil-based liquid, reacts to changes in the electromagnetic field. As the field strength varies, the ferrous particles align or disperse, altering the viscosity of the fluid.

(j) Altering Damping Characteristics:

The change in viscosity of the magnetorheological fluid directly affects the damping characteristics of the suspension system. When the fluid's viscosity increases, the damping force also increases, providing a stiffer suspension. Conversely, a decrease in viscosity results in a softer suspension.

(k) Real-Time Adaptability:

The entire process occurs in real-time, allowing the magnetic suspension system to adapt instantaneously to changing driving conditions. Whether encountering a smooth highway, uneven terrain, or aggressive cornering, the system continuously fine-tunes the damping settings for optimal ride comfort and handling performance.

(l) Smooth Transitions:

One of the strengths of magnetic suspension systems is their ability to provide a seamless transition between different damping settings. As the vehicle moves from one driving scenario to another, the system adjusts smoothly, ensuring a comfortable and controlled ride.

(m) Continuous Monitoring:

The sensors and ECU continually monitor the vehicle's dynamics, and the process repeats with every change in driving conditions. This continuous monitoring and adjustment result in a suspension system that is not only responsive but also anticipatory, enhancing both safety and performance.

The working of a Magnetic Suspension System involves a delicate dance between sensors, electronics, and fluid dynamics. This integration allows the system to provide an unparalleled driving experience by dynamically adapting to the ever-changing conditions of the road. The result is a balance between ride comfort and handling precision, showcasing the sophistication of modern automotive technology.

6. Requirements of Magnetic Suspension System:

The successful operation of a Magnetic Suspension System relies on various requirements to ensure optimal performance, longevity, and safety. These requirements encompass components, materials, and operational considerations. Let's explore the essential requirements of a Magnetic Suspension System:

(a) High - Quality Magnet-orheological Fluid:

The effectiveness of the system is heavily dependent on the quality of the magnetorheological fluid. This special fluid, containing ferrous particles suspended in an oil-based liquid, undergoes changes in viscosity in response to the magnetic field. High-quality fluid ensures consistent and reliable alterations in damping characteristics, contributing to the precision and responsiveness of the system.

(b) Durable Electromagnetic Dampers:

The electromagnetic dampers play a central role in the system's functioning. These components must be constructed with high-quality materials to withstand the rigors of daily driving and varying road conditions. Durability is crucial to ensure a long lifespan for the system and to prevent potential issues related to wear and tear.

(c) Robust Electronic Control Unit (ECU):

The ECU serves as the brain of the magnetic suspension system, processing vast amounts of data from sensors and making split-second decisions to adjust the system. A robust ECU is essential to handle the computational demands and to ensure the reliability and responsiveness of the system. It should also be designed to withstand temperature variations and potential environmental stresses.

(d) Precision Sensors:

Accurate and reliable sensor inputs are paramount for the proper functioning of the system. Accelerometers, wheel-speed sensors, and body position sensors must be of high precision to provide the ECU with accurate real-time data. Regular calibration and maintenance are essential to ensure the sensors' continued accuracy.

(e) Quality Manufacturing Standards:

The construction and assembly of all system components, including dampers, sensors, and the ECU, must adhere to stringent manufacturing standards. Quality control measures during the production process are essential to prevent defects and ensure the consistency of performance across multiple units.

(f) Effective Seals and Joints:

Seals and joints are crucial to prevent fluid leaks and maintain the integrity of the magnetorheological fluid within the dampers. Proper sealing ensures that the fluid remains contained, preventing contamination and ensuring the longevity of the system.

(g) Reliable Power Supply:

A stable and reliable power supply is essential for the continuous operation of the electromagnetic dampers and the electronic control unit. The power supply should be designed to handle the electrical demands of the system and provide consistent energy to all components.

(h) Adaptive Algorithms:

The algorithms embedded in the system's software play a crucial role in determining optimal damping settings. These algorithms should be adaptive and responsive, capable of adjusting the suspension characteristics in real-time based on the ever-changing driving conditions.

(j) Testing and Validation Protocols:

Rigorous testing and validation procedures are necessary to ensure that the magnetic suspension system meets safety and performance standards. This includes both laboratory testing and on-road testing to validate the system's functionality across various scenarios and conditions.

(k) Integration with Vehicle Dynamics:

The magnetic suspension system must be seamlessly integrated with the overall dynamics of the vehicle. The system should complement other vehicle control systems, such as ABS (Anti-lock Braking System) and stability control, to ensure a harmonious and coordinated response during different driving situations.

The requirements of a Magnetic Suspension System span various aspects, from the quality of components to the precision of sensors and the reliability of control algorithms. Meeting these requirements is essential to deliver a magnetic suspension system that excels in providing a balance between ride comfort and dynamic handling.

7. Conclusion:

In the ever-evolving landscape of automotive technology, Magnetic Suspension Systems stand as a remarkable feat of engineering. The seamless integration of electromagnetics, sensors, and real-time control provides a driving experience that adapts to the nuances of the road. As we continue to push the boundaries of innovation, Magnetic Suspension Systems exemplify the pursuit of both comfort and performance on the modern roadways.

0 Comments