Perfect Combination of 4 Stroke and 2 Stroke Engine

Introduction

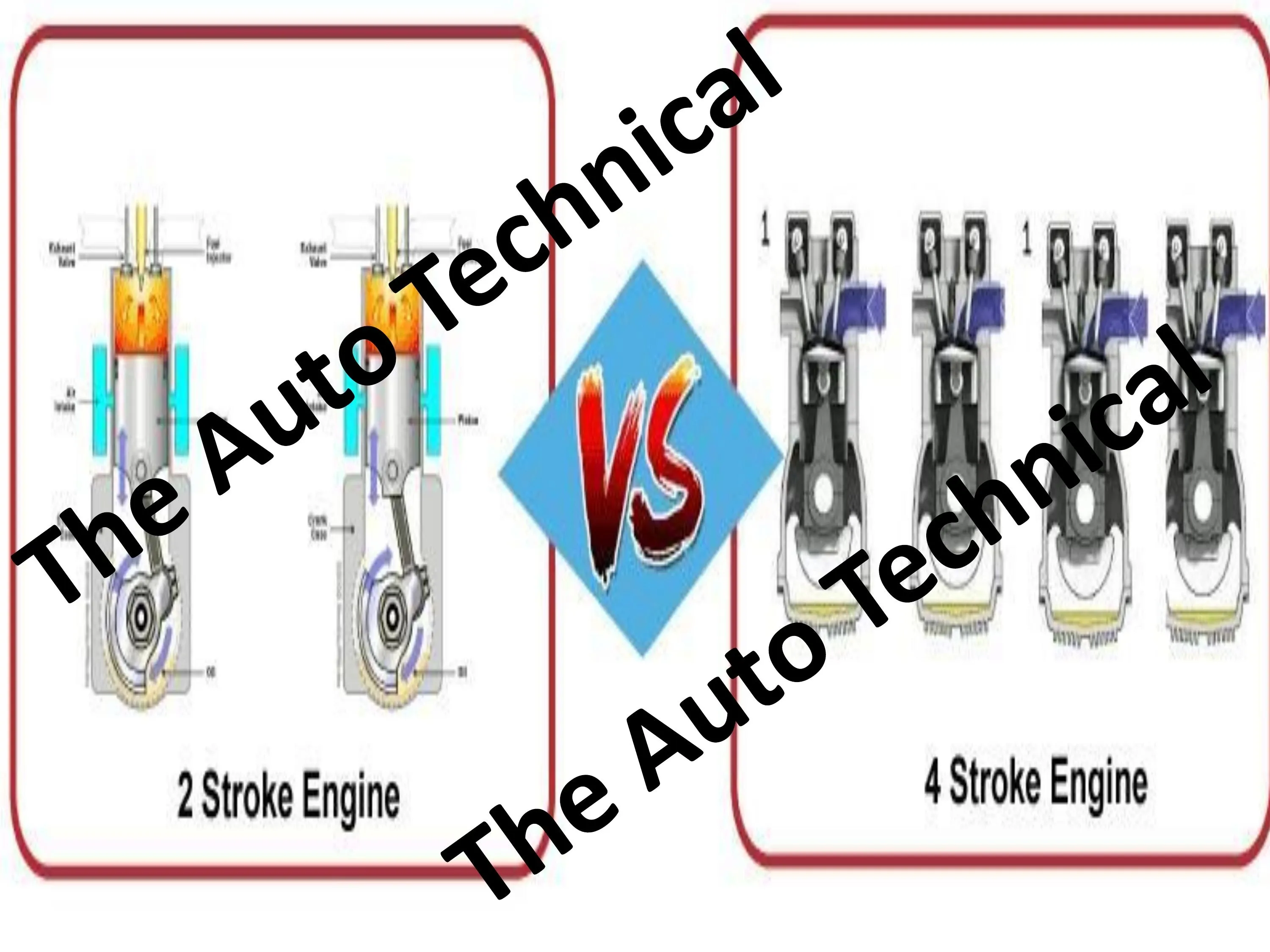

Engines are the beating heart of the automotive and industrial world, providing the power that drives our vehicles and machinery. Among the many types of engines, the four-stroke and two-stroke engines have long held their own distinct places in the realm of internal combustion.

However, in the quest for efficiency, performance, and reduced emissions, engineers have been exploring the concept of combining these two engine designs. This fusion of technologies, known as a combined four-stroke and two-stroke engine, represents a fascinating leap forward in the world of internal combustion engines.

In this article, we will delve into the basics of both four-stroke and two-stroke engines and explore how combining them can revolutionize various industries.

1. The Four-Stroke Engine

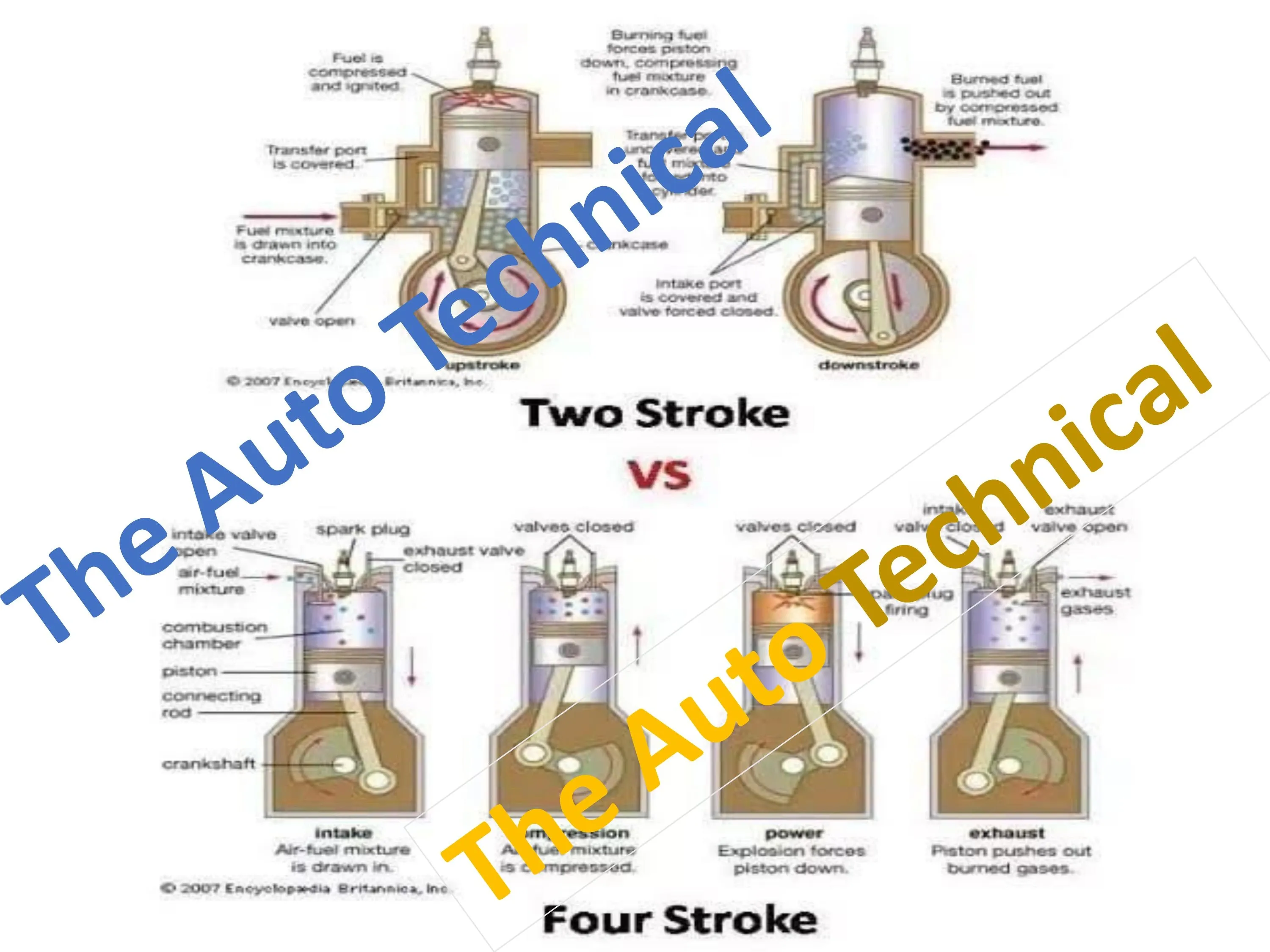

The four-stroke engine, also known as the four-cycle engine, is the most common type found in automobiles today. It operates on a cycle consisting of four distinct phases: intake, compression, power, and exhaust. Here's how it works:

a. Intake:

The engine draws in a mixture of air and fuel through the intake valve as the piston moves down.

b. Compression:

The piston moves back up, compressing the air-fuel mixture in the combustion chamber. This compression raises the temperature and pressure, making it ready for ignition.

c. Power:

A spark plug ignites the compressed mixture, causing an explosion. The resulting force pushes the piston down, turning the crankshaft and generating power.

d. Exhaust:

Finally, the exhaust valve opens, and the piston moves back up, expelling the burned gases from the combustion chamber.

Four-stroke engines are known for their fuel efficiency and low emissions, making them a preferred choice for most passenger vehicles.

2. The Two-Stroke Engine

In contrast, the two-stroke engine has only two primary phases: compression and power/exhaust. It is a simpler design, typically found in smaller engines such as those used in motorcycles, lawnmowers, and chainsaws. Here's how it works:

a. Compression and Power:

The piston moves up, compressing the air-fuel mixture and sealing it in the combustion chamber. As the piston reaches the top, a spark plug ignites the mixture, driving the piston back down and generating power.

b. Exhaust:

At the same time, the piston uncovers exhaust ports, allowing burned gases to escape.

Two-stroke engines are known for their lightweight and high power-to-weight ratio. However, they tend to be less fuel-efficient and produce higher emissions compared to four-stroke engines.

3. The Combined Four-Stroke and Two-Stroke Engine

The concept of combining both four-stroke and two-stroke technologies is an attempt to harness the strengths of each while mitigating their weaknesses. This innovative engine design aims to strike a balance between fuel efficiency, power output, and reduced emissions.

One approach to achieving this balance is the "compressed charge engine." In this design, the intake and compression strokes follow the four-stroke cycle, while the power and exhaust strokes follow the two-stroke cycle.

This arrangement allows for better fuel efficiency during the intake and compression phases, while retaining the power and simplicity of the two-stroke cycle during the power and exhaust phases.

4. Benefits of Combined Engines:

Improved Efficiency: By incorporating the four-stroke cycle for intake and compression, combined engines can achieve better fuel efficiency compared to traditional two-stroke engines.

a. Increased Power:

Leveraging the high power output of the two-stroke cycle, these engines can deliver more power without increasing size and weight significantly.

b. Reduced Emissions:

The four-stroke cycle's ability to burn fuel more cleanly, combined with advancements in emission control technology, helps in reducing harmful emissions.

c. Versatility:

These engines can be applied across various industries, from automobiles to marine vessels and small engines, making them highly adaptable.

d. Simplified Design:

The combination of cycles often simplifies the design, reducing maintenance and manufacturing costs.

Components of Combined Four-Stroke and Two-Stroke Engine

The concept of combined four-stroke and two-stroke engines has garnered significant attention in recent years due to its potential to revolutionize internal combustion engine technology.

These engines promise improved efficiency, reduced emissions, and increased power output by amalgamating the strengths of both four-stroke and two-stroke cycles.

To understand how this fusion works, we must delve into the key components that make up these innovative powerhouses.

1. Piston and Cylinder

a. Four-Stroke:

In the four-stroke cycle, the piston moves up and down within a cylinder. During the intake and compression strokes, the piston draws in the air-fuel mixture and compresses it.

b. Two-Stroke:

In the two-stroke cycle, the piston performs compression and power/exhaust strokes. It compresses the air-fuel mixture and generates power during the same downward stroke.

c. Combined Engine:

In combined engines, the piston plays a central role, coordinating its movement to accommodate both four-stroke and two-stroke cycles. This requires precise engineering to optimize efficiency and power output.

2. Valves

a. Four-Stroke:

Four-stroke engines have intake and exhaust valves that open and close to regulate the flow of air and exhaust gases.

b. Two-Stroke:

Traditional two-stroke engines often use ports instead of valves to control the flow of air and exhaust.

c. Combined Engine:

A combined engine typically retains the intake and exhaust valves of a four-stroke engine to ensure precise control over the intake and exhaust phases during the four-stroke cycle. This contributes to cleaner combustion and reduced emissions.

3. Crankshaft and Camshaft

a. Four-Stroke:

Four-stroke engines feature a crankshaft and camshaft. The crankshaft converts linear piston motion into rotational motion, while the camshaft controls valve timing.

b. Two-Stroke:

Two-stroke engines also have a crankshaft, but the camshaft is less complex or absent since valve timing is not as critical.

c. Combined Engine:

Combined engines must harmonize the rotational movement of the crankshaft with the varying valve timing requirements of the four-stroke and two-stroke cycles. This demands innovative engineering to optimize performance.

4. Fuel Injection and Ignition

a. Four-Stroke:

Four-stroke engines often use fuel injection systems and spark plugs for precise control of fuel delivery and ignition timing.

b. Two-Stroke:

Traditional two-stroke engines may use a carburetor and simpler ignition systems.

c. Combined Engine:

Combined engines frequently incorporate advanced fuel injection technology to ensure efficient fuel combustion during both four-stroke and two-stroke cycles. The ignition system must also be synchronized to accommodate the different phases.

5. Exhaust System

a. Four-Stroke:

Four-stroke engines usually have a separate exhaust stroke, with exhaust gases exiting through the exhaust valve.

b. Two-Stroke:

Two-stroke engines expel exhaust gases during the power/exhaust stroke through exhaust ports.

c. Combined Engine:

Combining both cycles necessitates a carefully designed exhaust system that accommodates the different timing requirements. This design aims to optimize power and minimize emissions.

Working of Four Stroke and Two Stroke Engine

Internal combustion engines power the majority of vehicles and machinery worldwide, providing the force needed to propel us forward. Among the various types of engines, four-stroke and two-stroke engines have long been at the forefront.

Here, we'll delve into the inner workings of these two engine types, exploring the fundamental differences in their operation.

1. Working of Four-Stroke Engine:

The four-stroke engine, also known as the four-cycle engine, follows a well-defined sequence of steps, each corresponding to one stroke of the piston. Here's a detailed breakdown of how it operates:

a. Intake Stroke:

The first stroke involves the piston moving down the cylinder.

As the piston descends, the intake valve opens.

A mixture of air and fuel is drawn into the cylinder from the surrounding environment.

b. Compression Stroke:

During the second stroke, the piston moves back up the cylinder.

Both the intake and exhaust valves remain closed.

The air-fuel mixture is compressed within the cylinder, raising its temperature and pressure.

c. Power Stroke:

The third stroke is where combustion takes place.

A spark plug ignites the compressed air-fuel mixture.

The resulting explosion forces the piston down the cylinder, creating mechanical energy.

This energy is transferred to the crankshaft, which converts it into rotary motion.

d Exhaust Stroke:

The final stroke is the exhaust phase.

As the piston moves back up, the exhaust valve opens.

The burned gases from combustion are expelled from the cylinder.

The four-stroke engine is known for its efficiency and low emissions. It is commonly found in most cars, trucks, and larger machinery.

2. Working of Two-Stroke Engine:

In contrast to the methodical four-stroke cycle, the two-stroke engine operates on a more streamlined process, utilizing just two strokes of the piston:

a. Compression and Power Stroke:

During the first stroke, the piston moves upward within the cylinder.

As it moves up, it compresses the air-fuel mixture that has already entered the cylinder.

When the piston reaches the top, a spark plug ignites the compressed mixture.

The resulting explosion drives the piston down the cylinder, generating power.

At the same time, the piston uncovers exhaust ports, allowing burned gases to escape.

The two-stroke engine is known for its simplicity and lightweight design, making it popular in smaller applications such as motorcycles, lawnmowers, and chainsaws.

However, it tends to be less fuel-efficient and produces higher emissions compared to four-stroke engines.

3. Comparing the Two

Understanding the differences in how these engines operate is essential for selecting the right one for a given application:

a. Efficiency:

Four-stroke engines are generally more fuel-efficient due to their precise control over intake, compression, and exhaust phases.

b. Power-to-weight Ratio:

Two-stroke engines have a higher power-to-weight ratio, making them suitable for applications where weight and power are critical.

c. Emissions:

Four-stroke engines produce fewer emissions, making them environmentally friendly. Two-stroke engines are known for higher emissions, especially when unburned oil is introduced into the fuel mix.

d. Maintenance:

Four-stroke engines typically require less maintenance due to their cleaner operation. Two-stroke engines may require more frequent maintenance.

Advantages and Disadvantages of Combined Four-Stroke and Two-Stroke Engines

The marriage of four-stroke and two-stroke engine technologies into a single powerplant, known as the combined four-stroke and two-stroke engine, has been a topic of interest and innovation in the world of internal combustion.

This hybrid engine design aims to capitalize on the strengths of both engine types while minimizing their respective weaknesses.

In this paragraph, we will explore the advantages and disadvantages of using combined four-stroke and two-stroke engines.

1. Advantages of Combined Four-Stroke and Two-Stroke Engines:

a. Improved Efficiency:

One of the primary benefits of combined engines is enhanced efficiency. By incorporating the four-stroke cycle for intake and compression and the two-stroke cycle for power and exhaust, these engines can achieve improved fuel economy, making them more environmentally friendly and cost-effective.

b. Increased Power Output:

The two-stroke cycle is known for its high power-to-weight ratio. By integrating it into the combined engine, manufacturers can achieve increased power output without significantly increasing the size or weight of the engine.

This makes it suitable for applications where power is critical, such as in marine vessels and power generators.

c. Reduced Emissions:

Combined engines have the potential to reduce harmful emissions compared to traditional two-stroke engines. The use of the four-stroke cycle for intake and compression allows for cleaner combustion, resulting in lower emissions of pollutants like nitrogen oxides and particulate matter.

d. Versatility:

These engines are highly adaptable and can be employed across various industries and applications, from automobiles and motorcycles to boats and small engines. Their versatility makes them a valuable option for different sectors.

e. Simplified Design:

Combining both cycles can often simplify the engine's design, reducing manufacturing and maintenance costs. Fewer components may lead to increased reliability and decreased downtime.

2. Disadvantages of Combined Four-Stroke and Two-Stroke Engines:

a. Complex Engineering:

Developing a combined engine that harmonizes the different cycles and their respective requirements is a complex engineering challenge. Achieving optimal performance while maintaining reliability and efficiency requires significant research and development.

b. Higher Manufacturing Costs:

The intricate design and precision required for combined engines can result in higher manufacturing costs. This could potentially make vehicles and machinery using these engines more expensive upfront.

c. Potential for Reduced Durability:

The high-revving nature of two-stroke engines may lead to increased wear and tear on engine components, potentially reducing the engine's overall durability. This can result in shorter engine lifespans compared to traditional four-stroke engines.

d. Limited Adoption:

While the concept of combined engines is promising, their adoption is still limited. Established engine designs, manufacturing processes, and consumer preferences can slow down the integration of this technology into the market.

e. Emission Challenges:

While combined engines have the potential to reduce emissions compared to traditional two-stroke engines, they may still face challenges in meeting stringent emission regulations, particularly in regions with strict environmental standards.

Recommendations for Implementing Combined Four-Stroke and Two-Stroke Engines in Army

The Army, known for its unwavering dedication to safeguarding the nation's borders and interests, constantly seeks ways to enhance its operational capabilities while maintaining efficiency and reducing environmental impact.

In this pursuit, the adoption of combined four-stroke and two-stroke engines presents a unique opportunity. This article offers recommendations for utilizing these innovative engines within the Indian Army's diverse operational requirements.

1. Assess Diverse Requirements:

The Indian Army operates a wide array of vehicles and equipment, from armored vehicles to generators and transportation fleets.

It's crucial to conduct a comprehensive assessment to identify specific applications where combined engines can offer advantages, such as improved power, efficiency, and lower emissions. Prioritize applications that require a balance of power and economy.

2. Focus on Fuel Efficiency:

Combined engines can significantly improve fuel efficiency, a key consideration for the Indian Army, especially in long-range operations and remote areas.

Opt for engines that demonstrate a substantial reduction in fuel consumption while maintaining the required power output.

3. Consider Environmental Impact:

Environmental sustainability aligns with the Indian Army's commitment to responsible practices. Choose combined engines that meet or exceed emission standards and incorporate advanced emission control technologies.

This will not only reduce the carbon footprint but also contribute to cleaner air in the areas where the army operates.

4. Evaluate Durability and Reliability:

Military operations often demand rigorous usage and require equipment that can withstand harsh conditions. Prioritize engines known for their durability and reliability to ensure consistent performance in the field.

5. Invest in Training and Maintenance:

Efficient operation and maintenance are vital for any engine fleet. Invest in comprehensive training programs for personnel responsible for operating and maintaining the combined engines. Ensure that there is a robust maintenance infrastructure in place to promptly address issues and minimize downtime.

6. Collaborate with Domestic Manufacturers:

The Indian Army can collaborate with domestic engine manufacturers to develop customized solutions that cater to its specific needs. This approach can lead to engines designed to perform optimally in Indian terrain and conditions.

7. Monitor Performance Actively:

Implement a proactive engine monitoring system to track metrics such as fuel consumption, emissions, and engine health. Regular performance assessments can identify areas for improvement and optimize engine operation.

8. Explore Hybrid Power Solutions:

Consider integrating hybrid power solutions alongside combined engines. Hybrid systems can provide additional advantages in terms of fuel savings and reduced noise levels, crucial for tactical operations.

9. Prioritize Strategic Mobility:

Incorporate combined engines into strategic mobility platforms, such as armored vehicles and troop carriers. These engines can enhance the power-to-weight ratio and maneuverability of military vehicles, ensuring they can operate effectively in a variety of terrains.

10. Plan for Future Sustainability:

As technology evolves, future-proof your engine fleet by selecting engines designed to accommodate emerging technologies, including alternative fuels and energy sources.

Conclusion

Implementing combined four-stroke and two-stroke engines in the Indian Army can be a strategic move to enhance operational efficiency, reduce fuel consumption, and minimize environmental impact.

By carefully assessing requirements, focusing on fuel efficiency, considering environmental factors, and collaborating with domestic manufacturers, the Army can harness the advantages of these innovative engines to strengthen its capabilities while contributing to a greener and more sustainable future.

With a strategic approach, combined engines can play a pivotal role in powering the force and safeguarding the nation's security.

.webp)

.webp)

0 Comments