Modern Technology of Gearing and Bearing

#SmartGear

#SmartGearwithSensor

#AdvanceGear

#SmartBearing

#AdvanceBearing

#CeramicBearing

Introduction:

In the realm of gearing, there's a growing trend towards precision and efficiency, with industries embracing advanced materials and manufacturing techniques to enhance performance. Additionally, there's an increased focus on compact designs and quieter operation, driven by the demand for more sophisticated and user-friendly machinery.

Bearing technology is also advancing, with a shift towards smart bearings equipped with sensors for real-time monitoring. This enables predictive maintenance, reducing downtime and improving overall reliability. Ceramic bearings are gaining popularity due to their durability and resistance to corrosion, especially in industries like aerospace and automotive.

Overall, the modern trends in gearing and bearing reflect a pursuit of higher performance, reduced environmental impact, and improved maintenance strategies.

Advance Gear Technology:

Advanced gear technology encompasses various innovative approaches aimed at improving efficiency, reliability, and performance in different applications. Here are some notable types:

1. Precision Gearing:

Advances in manufacturing processes allow for the production of gears with extremely tight tolerances, enhancing overall system efficiency and reducing noise.

2. Hypoid and Spiral Bevel Gears:

These gears are crucial in automotive and industrial applications. They provide efficient power transmission with minimal noise and vibration, making them ideal for high-performance systems.

3. Cycloidal Gearing:

Known for its smooth and shock-resistant operation, cycloidal gears are commonly used in robotics and high-precision machinery, offering improved torque transmission and accuracy.

4. Plastic Gearing:

With advancements in materials engineering, high-strength plastics are increasingly used in gears. These lightweight and corrosion-resistant gears find applications in diverse industries, including automotive and medical devices.

5. Magnetic Gearing:

Magnetic gears use magnetic forces instead of mechanical contact for power transmission. They offer benefits such as zero backlash, reduced maintenance, and improved efficiency, making them suitable for specific applications.

6. Harmonic Drive Systems:

Employing flexible components, harmonic drives provide high precision and torque in a compact design. They find applications in robotics and aerospace, where compactness and accuracy are critical.

7. Continuously Variable Transmissions (CVTs):

CVTs provide seamless and stepless gear ratio changes, improving fuel efficiency in vehicles. They are increasingly used in modern cars to optimize engine performance across different driving conditions.

8. Smart Gearing with Sensors:

Integration of sensors and data analytics into gears enables real-time monitoring of performance. This leads to predictive maintenance, minimizing downtime and extending the lifespan of gear systems.

These advancements in gear technology reflect a combination of material science, manufacturing innovations, and a focus on meeting the evolving needs of various industries.

Type of Smart Gears:

Smart gears encompass various types, each equipped with specific sensors and features tailored to their intended applications. Here are some notable types of smart gears:

1. Smart Industrial Gears:

Used in manufacturing and industrial machinery, these gears often incorporate sensors for monitoring factors like vibration, temperature, and load. They contribute to predictive maintenance strategies in factories, reducing downtime.

2. Aerospace Smart Gears:

In aviation and space applications, smart gears play a crucial role in monitoring critical parameters such as torque, temperature, and gear alignment. This enhances the safety and reliability of aerospace systems.

3. Automotive Smart Gears:

Found in modern vehicles, these gears utilize sensors to monitor gear performance, temperature, and wear. The data collected aids in optimizing engine efficiency, improving fuel economy, and supporting advanced driver-assistance systems.

4. Robotics and Mechatronics Gears:

Gears used in robots often incorporate sensors for precise motion control. These smart gears contribute to the accuracy and reliability of robotic movements, enhancing automation in various industries.

5. Medical Device Gears:

Gears used in medical equipment may be equipped with sensors for monitoring factors such as speed, force, and precision. This ensures the reliability and safety of medical devices during diagnostics and treatments.

6. Smart Actuator Gears:

Actuators, which are crucial in various systems, can be equipped with smart gears that monitor position, load, and performance. This is common in applications like valves, where precise control is essential.

7. Energy Sector Smart Gears:

Gears used in renewable energy systems, such as wind turbines, often incorporate sensors for monitoring factors like wind speed, torque, and vibration. This data aids in optimizing energy production and ensuring the longevity of the equipment.

8. IoT-Enabled Gears:

Gears integrated into Internet of Things (IoT) ecosystems can communicate data to central platforms. This connectivity allows for remote monitoring, real-time analytics, and seamless integration with other smart devices in a network.

These types of smart gears showcase the diverse applications and industries benefiting from the integration of sensor technologies to enhance performance, optimize maintenance, and contribute to the broader ecosystem of smart and connected systems.

Type of Automotive Smart Gears:

In the automotive industry, several types of smart gears are integrated into vehicles to enhance performance, efficiency, and safety. Here are some key types:

1. Smart Transmission Gears:

Modern transmissions incorporate sensors to monitor factors such as gear position, speed, and temperature. This data is utilized for optimal gear shifting, improving fuel efficiency, and enhancing overall driving experience.

2. Electric Vehicle (EV) Gear Systems:

Electric vehicles utilize smart gears with sensors to manage power delivery from the electric motor. These gears help optimize energy usage, monitor motor performance, and contribute to regenerative braking systems.

3. Smart Differential Gears:

Differential gears in vehicles can be equipped with sensors to monitor torque distribution between wheels. This technology improves traction control, stability, and enhances performance, especially in varying driving conditions.

4. Automated Manual Transmission (AMT) Gears:

Smart gears in AMT systems use sensors to determine the optimal time for gear changes. This contributes to smoother transitions and improved fuel efficiency compared to traditional manual transmissions.

5. Advanced Driver-Assistance System (ADAS) Gears:

Gears integrated into systems like adaptive cruise control and lane-keeping assist utilize sensors to monitor the vehicle's surroundings. These smart gears play a role in the precise control and responsiveness of ADAS features.

6. CVT (Continuously Variable Transmission) Systems:

CVT gears use a belt and pulley system, and sensors monitor parameters like engine speed and load to continuously adjust the gear ratio. This results in smoother acceleration and improved fuel efficiency.

7. Smart Gearbox Components:

Various components within the gearbox, such as actuators and clutches, may incorporate sensors. These sensors help optimize gear engagement, reduce wear, and contribute to overall transmission reliability.

8. IoT-Connected Gears:

With the rise of connected vehicles, gears integrated into the Internet of Things (IoT) ecosystem can communicate data to the vehicle's central control system. This connectivity allows for real-time monitoring, diagnostics, and remote updates.

The integration of sensors and smart technologies into automotive gears contributes to improved fuel efficiency, enhanced safety features, and a more seamless driving experience in both traditional and electric vehicles.

How do Smart Gears with Sensors Work:

Smart gears with sensors incorporate various sensor technologies to monitor key parameters and conditions during operation. The integration of sensors allows for real-time data collection, enabling performance optimization, predictive maintenance, and improved overall efficiency. Here's a general overview of how smart gears with sensors work:

1. Sensor Types:

Smart gears can be equipped with different types of sensors, including vibration sensors, temperature sensors, load sensors, and position sensors. These sensors are strategically placed to capture relevant data.

2. Data Collection:

During gear operation, sensors continuously collect data related to factors such as vibration levels, temperature variations, applied loads, and gear position. These data points offer insights into the gear's performance and the surrounding operating conditions.

3. Condition Monitoring:

The collected data is analyzed in real-time or periodically to assess the condition of the gear. Unusual patterns, vibrations, or deviations from normal operating parameters can indicate potential issues or the need for maintenance.

4. Predictive Maintenance:

By leveraging the information gathered, smart gears can predict potential failures or maintenance needs before they lead to a breakdown. This proactive approach helps in scheduling maintenance activities at optimal times, minimizing downtime and reducing overall maintenance costs.

5. Communication:

In many cases, smart gears are equipped with communication capabilities, allowing them to transmit data to a central control system or a cloud-based platform. This facilitates remote monitoring and management, especially in industrial settings.

6. Integration with Control Systems:

The data from sensors can be integrated into the overall control system of a machine or a larger system. This integration enables dynamic adjustments based on real-time operating conditions, improving the efficiency and reliability of the entire system.

7. Feedback Loop:

Smart gears can provide feedback to control systems, enabling automatic adjustments to optimize performance. For example, in robotic systems, the feedback from smart gears can be used to refine movements and increase precision.

In summary, smart gears with sensors enhance operational visibility, enable predictive maintenance, and contribute to the overall efficiency and reliability of mechanical systems by leveraging real-time data and advanced analytics.

Type of Automotive Smart Bearings:

Here are some types of bearings that were considered advanced in the automotive industry:

1. Smart Sensor Bearings:

These bearings are equipped with sensors that monitor factors like temperature, speed, and load. The data collected helps in real-time condition monitoring, enabling predictive maintenance and improving overall reliability.

2. Magnetic Bearings:

While not yet widespread in all automotive applications, magnetic bearings use magnetic fields for levitation and support. They have the potential to reduce friction, enhance efficiency, and require minimal maintenance.

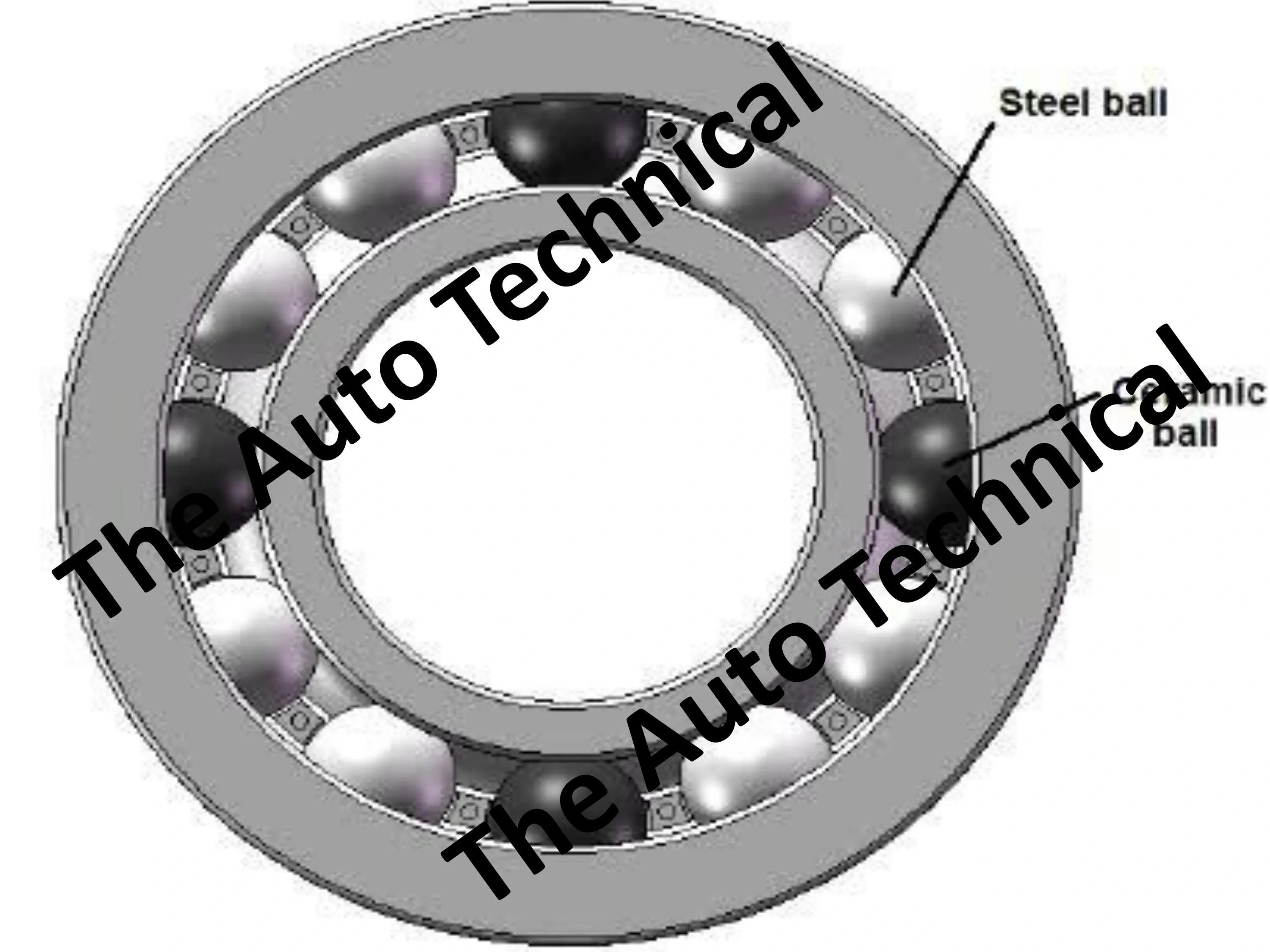

3. Ceramic Bearings:

Bearings made from ceramic materials, such as silicon nitride, offer advantages like high strength, reduced weight, and resistance to corrosion. These bearings are often used in high-performance and racing vehicles for improved durability.

4. Roller Bearings with Advanced Coatings:

Roller bearings with specialized coatings, such as diamond-like carbon (DLC) coatings, provide increased hardness and reduced friction. These coatings contribute to longer bearing life and improved efficiency.

5. Hub Unit Bearings with Integrated Sensors:

Hub unit bearings with built-in sensors are common in modern vehicles. These sensors monitor wheel speed and contribute to the operation of anti-lock braking systems (ABS) and traction control systems.

6. Self-Lubricating Bearings:

Bearings with self-lubricating properties reduce the need for external lubrication maintenance. This feature contributes to longer life and decreased friction, improving overall efficiency.

7. Energy-Efficient Bearings:

Bearings designed with a focus on reducing energy consumption contribute to improved fuel efficiency in vehicles. These bearings often incorporate advanced materials and design optimizations.

8. Hybrid Bearings:

Hybrid bearings combine elements of traditional bearings with ceramic components. These bearings aim to provide the benefits of both materials, such as reduced weight, increased durability, and improved performance.

It's essential to check the latest information from automotive manufacturers and bearing suppliers to stay updated on the most recent advancements in smart bearing technology in the automotive industry.

About Flexible Roller Bearing:

Flexible roller bearings, or sometimes referred to as compliant roller bearings, are a type of bearing designed to provide flexibility in certain applications. The concept involves using compliant or flexible elements within the bearing structure, allowing for controlled movement and deformation. Here are some key aspects:

1. Design and Structure:

Flexible roller bearings typically have a unique design that incorporates flexible elements, such as springs or compliant materials, along with traditional roller bearing components. This design allows for controlled deformation under certain loads or misalignments.

2. Misalignment Compensation:

One of the primary purposes of flexible roller bearings is to compensate for misalignments between shafts or other components. The flexibility in the design enables the bearing to accommodate deviations from perfect alignment, reducing stress on the bearing and improving overall performance.

3. Reduced Friction and Wear:

The compliant elements in flexible roller bearings can help reduce friction and wear, particularly in applications where misalignments are common. This can contribute to longer bearing life and improved efficiency.

4. Applications:

Flexible roller bearings find applications in systems where there may be dynamic loads, vibrations, or misalignments. They are commonly used in various industrial machinery, conveyor systems, and certain automotive applications.

5. Compliance Control:

Depending on the design, some flexible roller bearings allow for control over the level of compliance or flexibility. This adaptability makes them suitable for diverse applications with varying requirements for misalignment compensation.

6. Maintenance Considerations:

While flexible roller bearings can offer advantages in certain scenarios, it's essential to consider maintenance requirements and the specific conditions of use. Regular inspection is often necessary to ensure that the flexible elements are functioning as intended.

As technology advances, there may be new developments or variations in the design and application of flexible roller bearings. For the latest and most specific information, it's recommended to check with bearing manufacturers or industry publications for updates in this field.

.jpg)

.webp)

.webp)

0 Comments