What is the Fluid Fly Wheel and Torque Converter, principle of the fluid fly wheel and torque converter

Fluid Fly Wheel and torque converter:-

As you all know there is a clutch inside the car to isolate the drive of the engine and transmission and back one, but friends it works on pressing the clutch, clutch pedal means that this manual or can be called mechanical clutch.

What is Fluid fly wheel, fluid fly wheel kya hai

Then the automobile engineers thought that something which should be installed on the side of the clutch and in place of the clutch, but the driver does not have to press the clutch pedal, which means that if the clutching is required, it becomes automatic. So the instrument which was replaced in this place is called Fluid fly Wheel.

Work of the fluid fly wheel and torque converter:-

What is torque converter, torque converter kya hai

Working Principle of Fluid fly wheel and torque converter:-

Fluid Fly Wheel is works on the principal of Hydraulic Pressure and centrifugal force. Now understand this in detail through example -

1. Rotary Flow:-

2. Tangential Flow:-

3. Vortex Flow:-

Fluid Fly Wheel works on these three principles.

What is Bounce back effect

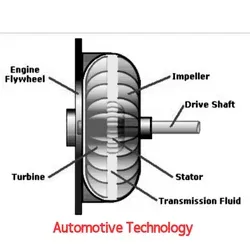

Parts of the Fluid Fly Wheel and torque converter:-

1. Drive member or Impeller:-

It is fitted with the fly wheel of the engine.

2. Driven member or Turbine:-

It is connected with the shaft of the gear box.

3. Housing:-

There are two member drive and driven member fitted inside it and fluid is filled in it.

Working Function of the fluid fly wheel and torque converter:-

1. Under Idling Condition (when the car is not running when it is started):-

In this condition the drive of the engine continuously comes to the impeller of the fluid fly wheel which causes the impeller to rotate and housing Throws the filled fluid into the turbine. But its speed is not so high that it cannot rotate the turbine at that time due to the weight of the vehicle more than the power of the engine and the ground resistance, the car stays tight and the engine starts, in such a condition 100% slipping occur inside the fluid fly wheel.

2. At low or medium speed (when the car moves at a low speed):-

As the RPM of the engine is further increased and the accelerator pedal is pressed, the engine gets more power which causes the impeller and speed to rotate and throws the filled fluid inside the housing on top of the turbine so that the turbine moves slowly starts and the car starts moving in slow motion, in this condition some slipping occurs.

3. At High Speed (when the vehicle is running at full speed):-

When the vehicle is running at full speed then the impeller rotates at full speed and throws the fluid over the turbine with full pressure, so that the turbine also rotates with full force and drives goes to the wheels through the transmission and the vehicle runs at full speed. Even in this condition, slipping from 2% to 3% occurs.

what is Slipping:-

Advantages of Fluid Fly Wheel and torque converter:-

1. No use of Clutch Pedal.

2. Malfunction occurs less often.

3. Adjustment is not required.

4. Clutch plate is not worn in the same way.

5. Maintenance is less.

6. Easy drive.

7. If there is a sudden load then there is slipping which does not affect the engine.

Disadvantages of Fluid Fly Wheel and torque converter:-

1. If the level of fluid decreases below 85% then its working capacity is reduced.

2. It is more likely to leak fluid.

3. It takes longer to repair.

4. Due to repeated slipping, the fluid will become hot and vapour will be formed which will reduce the efficiency of the fly wheel.

Keeping in mind all these losses, some changes were made in it to overcome its disadvantage and what they are. Let's know about this-

(i) Stator was installed:-

(a) what is Bounce Back Effect:-

If the fluid is thrown on a wall, than some fluid sticks to the wall and some collides and comes back, this is called the bounce back effect. This was done between the Impeller and the turbine inside the Fluid Fly Wheel before installing the effect stator.

(ii) Lock-up Clutch:-

Because of the lock up clutch the problem ended which is engine not starting while pulling or pushing the vehicle.

It has a retched type lock-up clutch which is free when the engine starts, but when pushed, in other words, when the drive comes from wheel to the engine, then the lock up clutch keep interlock the impeller and turbine.

Important:-

Fluid Fly Wheel is used in today's modern vehicles which have auto-transmission.

0 Comments